PRECISE AUTOMATIC LABEL APPLICATORS

For over 35 years, Gernep has been a global leader in rotary labeling machines, proudly engineered and manufactured in Bavaria, Germany. Our team of 100+ skilled professionals is dedicated to designing and building customized labeling systems that deliver precision, speed, and long-term reliability for a wide range of industries.

From wet glue and hot melt labeling to pressure-sensitive labelers, Gernep’s solutions are known for their efficiency, compliance, and ability to meet the most demanding production requirements. We specialize exclusively in rotary labeling technology – an advantage that has helped us set the benchmark for performance, innovation, and machine uptime.

Our labelers are engineered for fast changeovers, easy maintenance, and intuitive operation, helping manufacturers reduce downtime and increase throughput. Whether you’re labeling bottles, jars, or containers of various shapes and materials, Gernep ensures high-quality results across all applications.

Labeling system services

The Gernep portfolio includes rotary labelers for cold glue cut & stack labels, hot glue cut & stack labels, pressure-sensitive labels, and rollfed hot melt labels. Our solutions offer the flexibility needed to meet future labeling requirements while remaining cost-effective.

For ultimate versatility, it is possible to combine any of these labeling technologies and integrate aggregates for tamper-evident labeling, tax strip labeling, and foil labeling (under or over cap) for various bottle sizes and shapes to meet your production requirements.

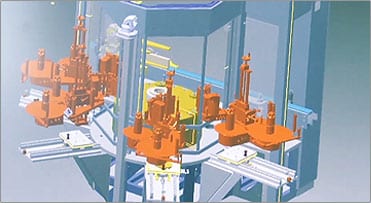

Project Drafting

Our efficient development team members find an ideal solution for every planning requirement, and with over 35 years of experience in planning labeling systems, we ensure maximum investment security. We provide quick and uncomplicated advice on-site and investigate solutions for your personalized system on state-of-the-art CAD systems. With Gernep, you receive ongoing creative and professional support in all critical planning phases.

Consulting

Our consulting and performance range is not limited to new systems. We use our three-decade-long experience to propel system expansions, modernizations, or economic and energy updates for existing systems. We partner with our clients to offer individual, tailor-made solutions that ideally combine investment, efficiency, and energy efficiency.

Construction

GERNEP machinery typically features rational modular construction, variability in the structure of the labeling units, and the option of flexible extensions in respect of subsequent labeling requirements in every construction. Developing customer-centric labeling machines allows maximum performance and precision while permitting rational upgrading to align with changing needs. Our machinery reflects the latest technological innovation through continuous advancement.

System integration

As a competent service partner, we are not satisfied with merely setting up and assembling on site. If necessary or requested, we also deal with integrating our machinery to existing systems, whether it be controlling or the shipping agents’ activities concerning our labeling machines. We incorporate the planning of necessary leads and processes of the shipping agents and ensure that the automatic control is perfect in all performance areas.