With our unlimited equipment options, we can meet every bottle shape and equipment requirement. Whether pre-cut labels, design labels with free shapes or self-adhesive labels from the roll, such as the increasingly popular no-label look.

Wine Bottle Labelers Tailor Made for this Industry

By using cost-effective film labels to decorative no-label look labels – in every performance range – we offer the wine and spirits industry cost-effective, flexible machines that also enable future requirements through profitable upgrading or conversion.

GLASS AND PLASTIC BOTTLES

Develop new SKUS without investing in new machinery. Run glass or plastic bottles of any shape on the same machine with servo-driven interchangeable bottle plates.

SELF ADHESIVE, COLD GLUE OR COMBINATION

Get all the flexibility you need, and answer marketing demands for improved brand experience.

MULTIPLE LABELS ON THE SAME BOTTLE

From awards stickers, to bottle neck decorations, the versatility of Gernep machines unleash unlimited possibilities.

ANY LABEL FORMAT

From paper or film labels to waterproof self-adhesive labels such as the No-Label-Look, tailor-made for our machines, the versatile options unleash huge potential.

MULTIPLE BOTTLE ORIENTATION

Mechanical, optical and camera based orientation allowing precise bottles and labels positioning, at up to 600 bottles per minute.

SERVO BOTTLE PLATE

Reduces change part cost and makes for fast changeovers. Our servo bottle plates uses a recallable program to rotate every bottle size to suit, ensuring perfect application of the labels for each set up.

TRACEABILITY READY

Bring the transparency consumer calls for by seamlessly adding coding, inspection, aggregation, sales traceability and counterfake management system.

AUTOMATIC INSPECTION

Label-related defects are the most common cause of product recalls. Prevent the problem at the source with label placement and label presence inspection, automatically rejecting faulty bottles.

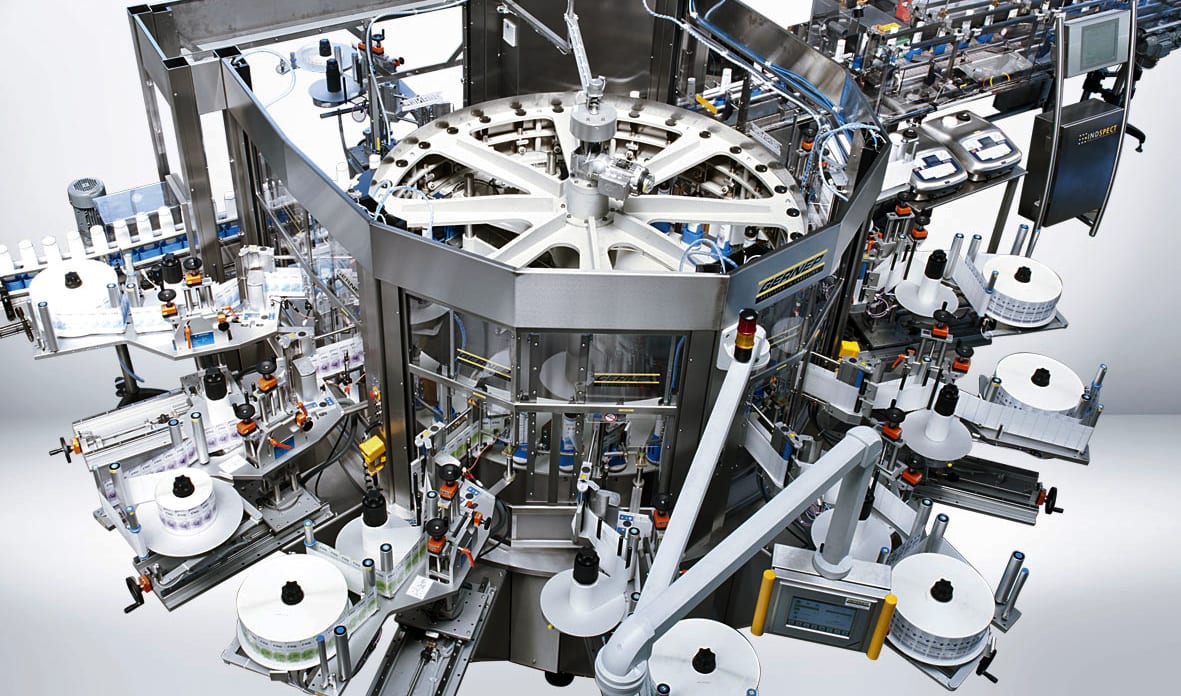

GERNEP LABELING SYSTEMS

YOUR SALES & SERVICE PARTNER IN NORTH-AMERICA

Technology

Performance and versatility are equally important when it comes to labeling systems for liquor and spirit bottles. With that mind, Gernep has developped the Soluta Rotary Labeler Series to apply pressure-sensitive labels to almost any shape or size of bottles reliably. In many case, the slightly higher cost of PS Labels (compared to cut & stack labels) is offset by the low price of label size parts, the quick changeovers and because no cleaning is required. Rotary pressure-sensitive labelers also works with different material (paper, clear plastic) and unlimited graphic options with shapes, sizes and finish. Gernep is using servo-driven Label Applicators which are perfectly integrated with the main control of the Soluta Rotary Labeler and all parameters are memorized by the PLC for quick format changeovers.

Features

- Universal label sensor (clear or opaque labels)

- Independent label applicators

- Up to 8 label applicators on 1 frame

- Modular system depending of needs

- Programmable servo motors

- Easy positioning of the labels by 4/5-way setting

- Label positions can be saved

- Intelligent label management

- One-to-one label rolls vs waste paper

- Redundant / Zero downtime mode

Advantages

- Low cost of label format parts

- Shorter changeover times

- Very short cleaning time

- Shorter cleaning and servicing times

- Innovative, exclusive, label designs feasible

- Processing of No-Label-Look labels

- Allow water-resistant plastic labels

- Possibility of combining with other modules

- Customized infeed and outfeed conveyors

Technology

Even tried and tested methods can be improved. Gernep has set new standards in compactness, ease of maintenance and ease of use with their newly designed cold glue labeler. In addition to proven parts such as removable and adjustable rubber glue palettes, stainless steel glue roller, split glue scraper blade for glue-saving application and oil lubricated gears, the new cold glue labeling station was designed to be more attractive appearance, compact, hermetically sealed against condensate penetration and easier to operate and maintain.

Features

- Overlay gearbox, for on-the-fly label position adjustment

- Oil bath for gears, giving long life service.

- Hermetically protected against water and condensation.

- Wear resistant glue pallets made of rubber.

- Glue pallets are removable.

- Glue pallets adjustable for optimum glue pattern.

Advantages

- Low-cost of labels

- Non-stop operation / no roll changeovers

- Neck, tamper-evident label or foil-over-cap

- Automatic “no bottle – no label –no glue”

- On-the-fly label position adjustment

- Maintenance free

- Heated glue pump

- Combination of PS Label applicator

- Customized infeed and outfeed conveyors