20 Mar Boost Your Packaging Line with Hot Melt Rotary Labelers for Tamper-Evident Applications

Why More North American Brands Are Turning to Hot Melt Rotary Labelers for Tamper-Evident Applications

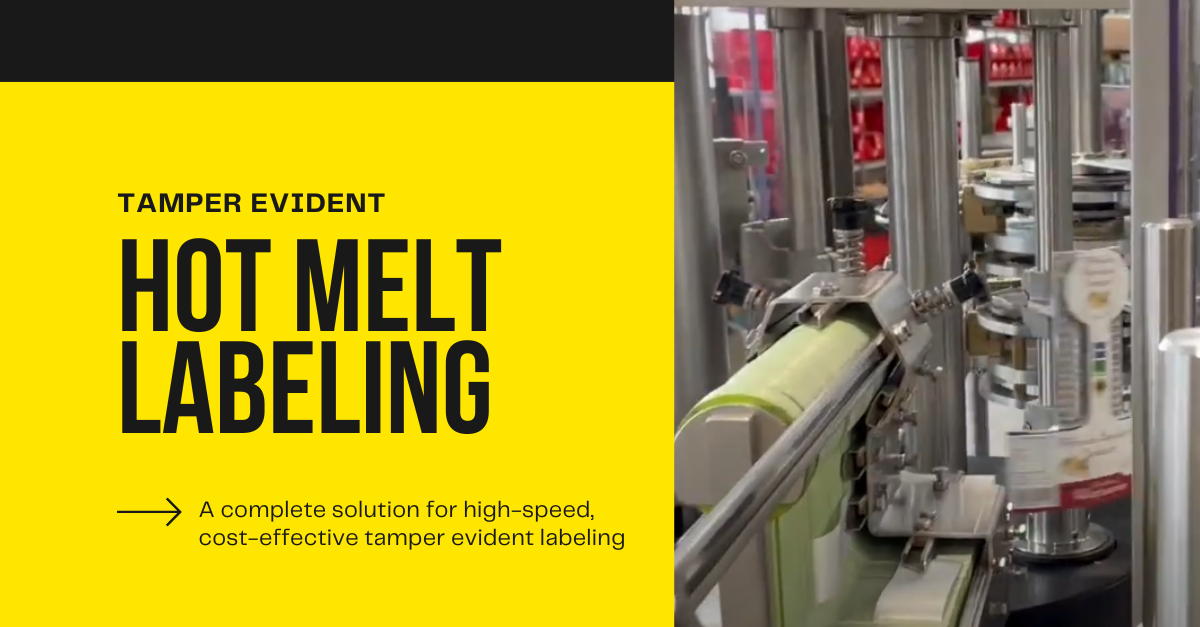

Watch the video below to see this solution in action!

If you’re in food & beverage, personal care, pharmaceuticals, or household products, you know how critical tamper-evident packaging is for customer trust and compliance. But here’s the thing—most labeling systems that offer tamper-evidence also bring higher costs and more complexity to your packaging line.

Our Rollina hot melt rotary labelers are a high-speed, space-saving solution that’s quietly becoming a favorite across North American manufacturing floors!

What makes hot melt rotary labelers stand out?

These systems apply a single cut & stack label that wraps around the body of your product and includes additional tamper-evident coverage on the cap—all in one smooth process.

Unlike pressure-sensitive labeling systems or shrink bands (which require sleeve applicators and heat tunnels), hot glue rotary labelers keep things simple and cost-efficient. We’re talking lower upfront costs, fewer components, and reduced energy consumption. In fact, many companies are slashing both their material and operational expenses when switching to this method.

How fast can they go?

Our hot glue rotary labelers don’t just streamline the process—they fly. With speeds of up to 400 containers per minute, they’re built for high-volume production lines that can’t afford downtime. And with non-stop operation, you can change label rolls without bringing your entire line to a halt.