17 Sep FLECTRA: A New Modular Labeling Machine for Diverse Industries

What is FLECTRA?

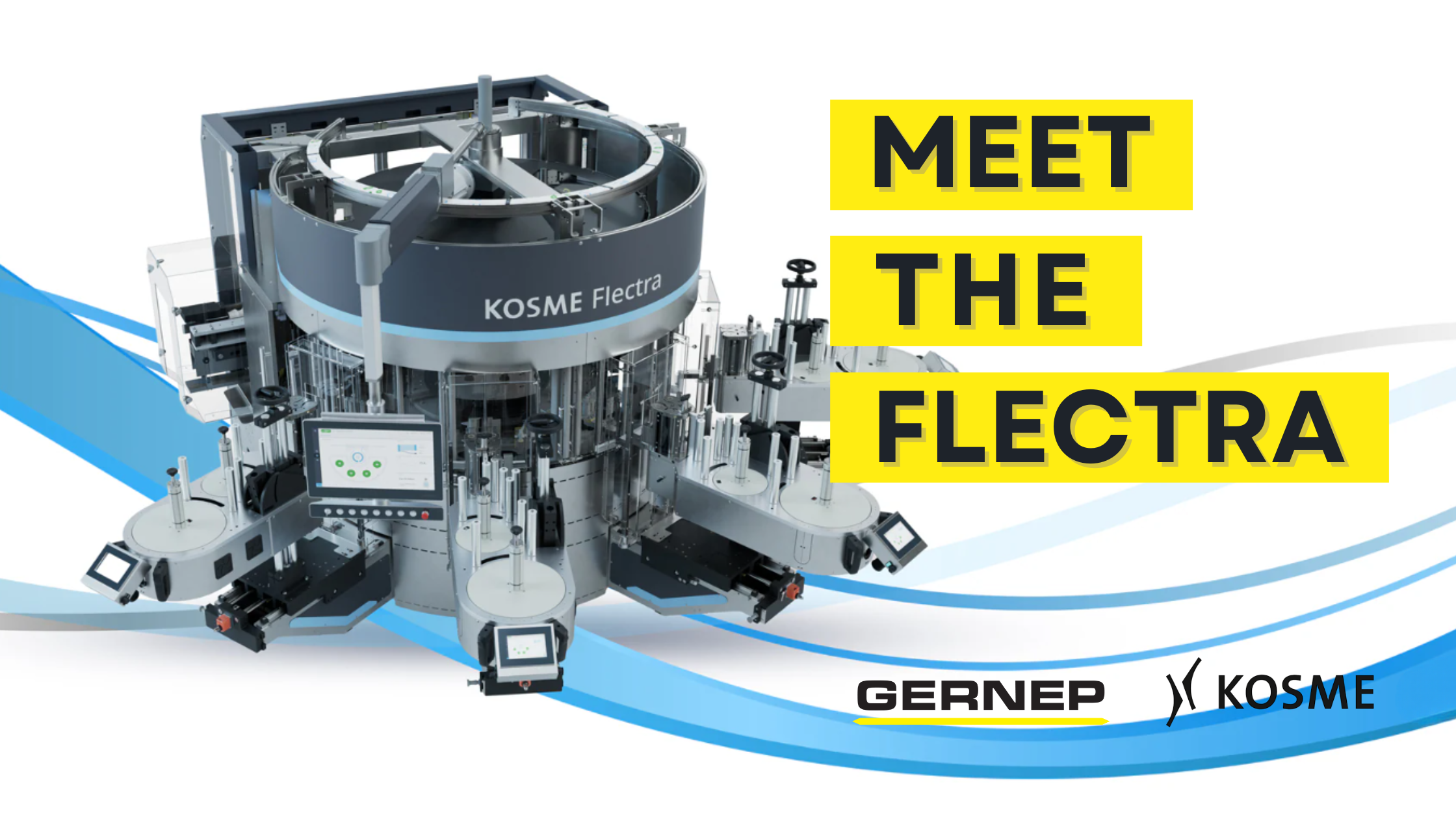

Flectra is the new next-generation modular labelling machine, born from the merger of expertise across Kosme (Italy, Austria, FBA) and Gernep – all under Krones’ Compact Class unit. Krones It’s designed for flexibility across industries (beverages, liquid food, personal care, pharma) and for manufacturers with low-to-medium output volumes.

FLECTRA Features

Feature

What it’s for

Benefits

Modular design (pre-modular or fully modular)

You can swap labelling units (e.g. self-adhesive vs cold-glue) via trolleys; plug-and-play setup; automatic parameter settings.

Reduces downtime when changing product types; lowers overhead for changeovers. Flexibility means shorter lead times from order to production readiness.

Self-adhesive station up to ~100 m/min; cold-glue up to 24,000 bottles/hour

Uses servo motors, automatic axis adjustment; the cold-glue unit uses polygon shafts, oil-circulating lubrication.

High speed for self-adhesive; cold glue can be more economical in some label types / regulatory contexts. Precision = less waste and rejects.

Improved format change, better hygiene & accessibility

Format changes are faster; cleaning easier; tool-free where possible; suspended aggregates; labyrinth sealing; new baseplate (“Click-Clack”) design.

Saves labour costs; reduces risk of contamination; faster turnaround between runs. For regulated industries especially (pharma, food), hygiene matters a lot.

Smart alignment & inspection systems

Optical sensors, 360° bottle rotation for alignment based on embossing, seam, graphics; high-res cameras; LED lighting; OCR/deep-learning for detecting overlaps, barcodes, etc.

Minimises errors, reduces manual inspection; improves brand consistency; reduces recall or rejection risk. Good for traceability.

Modern, user-friendly control interface

24-inch Full HD flat touchscreen; 270° swivel arm; hygienic design; keypads; central HMI; integration with Krones Operation Platform.

Shorter training time; fewer operator errors; real‐time monitoring; better maintenance scheduling. Gives management dashboard visibility.

The Added Value of FLECTRA – A New Modular Labeling Machine

Putting together those features, here are the concrete benefits:

-

-

- Lower Total Cost of Ownership (TCO): By cutting changeover times, reducing waste (through precision labelling and inspection), and simplifying maintenance, Flectra can reduce both operating costs and downtime-related losses.

- Scalability + Future-proofing: With its modular setup, producers can adapt as their product line grows or shifts. Rather than buying new machines, they can reconfigure labelling units. Also, integration with digital services helps with traceability, sustainability reporting, etc.

- Quality and Compliance: For industries with strict regulatory or quality requirements (e.g. food safety, pharma), hygiene, accurate labeling, and inspection are not just “nice to have”—they’re essential. Flectra’s design addresses that.

- Flexibility for Diverse Product Portfolios: If you have many SKUs (size, shape, label material), or run seasonal / short-run products, this machine reduces trade-offs between speed, accuracy, and cost.

- Faster ROI & Quicker Deployment: Krones claims standard configurations can be delivered in ~12 weeks and installed by a single engineer. Krones That means less time waiting, more time producing.

-

Every innovation comes with a few things to weigh.

Flectra’s upfront investment may be higher than older machines, but its flexibility, speed, and accuracy deliver long-term gains. For unusual shapes or specialty labels, a touch of customization may still be needed, and like any high-tech system, strong local service and spare parts support are key. Add in its smart digital features, which shine brightest with the right infrastructure and training, and you’ve got a Modular Labeling Machine that’s ready to take your production to the next level.

Who Will Benefit Most from Flectra

The Flectra Modular Labeling Machine is especially valuable for brands and co-packers managing a wide range of SKUs or frequent labelling changes, where flexibility can make or break efficiency. It’s also a strong fit for low- to medium-volume producers still relying on older, less adaptable equipment that often forces compromises on hygiene, speed, or accuracy. Industries under strict regulatory or traceability requirements—such as pharmaceuticals, personal care, and food and beverage—stand to gain from its precision and compliance-ready design. Producers aiming to cut waste and reduce product rejections will benefit from its advanced inspection and quality control features, while operations constrained by changeover times and labour costs will find its modular design and user-friendly setup a powerful way to streamline production.

Flectra is more than just “another labeller”, it’s a convergence of flexibility, precision, hygiene, and digital readiness. For producers facing fast-changing markets (consumer preferences, regulations, packaging trends), it can be a game-changer. The key is to assess your current bottlenecks (changeovers? rejects? labour? hygiene compliance?) and map where Flectra’s strengths align best with your pain points.