Rotary Labeler Equipment & Options

Bottle plate control system

The bottle plates are controlled mechanically via cam segments, an efficient belt drive, or computer-controlled servo motors depending on the machine model and the requirement. Our machinery can perform multiple container orientations following labeling specifications and meet the requirements for precise label placement.

Camera-based container orientation

Bottle and container orientation is prompted by glass seams, reliefs, clip-locks, and orientation marks.

Clamping star

Equipping our machinery with clamping stars in the inlet or discharge permits frequent set-up changes when handling bottles with minor diameter differences. The clamping stars are also ideal for targeted cup fixing, sealing applications, clip-locks, and tax labels, as well as with camera-based or photo-electronic orientation.

Non-stop function with self-adhesive labelling

Non-stop function with two dispensers per label, free-standing loop pre-winder, or free-standing automatic splicer for uninterrupted continuous operation.

Camera-based label monitoring

To monitor the presence and fixation of labels, we supply individual inspection solutions and complete with ejection systems such as bad part pushers or segment removal.

Mechanical alignment of clip-lock bottles

Machinery equipped with an orientation star at the bottle inlet ensures precise orientation of labeling and clip-lock bottles. Labels are gently brushed on in the machine and at a separate pressing station at the discharge star.

Mechanical Container Orientation

Photo-electronic container aligner

Our photo-electronic container orientation with surrounding sensors is the economical solution for aligning to distinctive features such as sparkling wine cap marks.

Metal foil application

Our metal foil application system consists of a magazine and palette set and a separate brushing station designed for the under-top and over-top foiling of the bottle neck. Perfectly aligned positioning with the front label results from gentle pressure, and a visually perfect closure and neck area is completed at the brushing station.

Tamper Evident Labeling, Sealing strip and cap labelling

Sealing and cap labels (with and without sealing tabs) are applied to any container by a separate labeling aggregate that meets individual requirements. Gluing takes place using wet glue or self-adhesive labels.

Tamper Evident Tax Strip Labeling

To process tax strip labels on bottles of wine and spirits, we supply a unique aggregate integrated into the machine for wet glue labeling. Like all of our additional equipment, this type of tamper evident label applicator is available from the factory immediately or can be prepared for retrofitting.

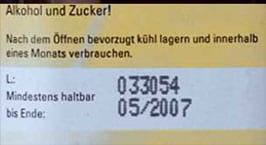

Dating/Coding

We can apply control and test data such as code numbers, batch & content information, the date, and other information to almost any area of the label or bottle with our date marking unit.

Depending on the requirement, we use inkjet printers, laser printers, or simple stamps. All systems allow the use of various fonts and colors.

-

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022

Bottle Labeling

Design

Rotary Labelers

-

Spoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

28 February, 2022

Rotary Labelers

Trouble Shooting