5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary Labelers

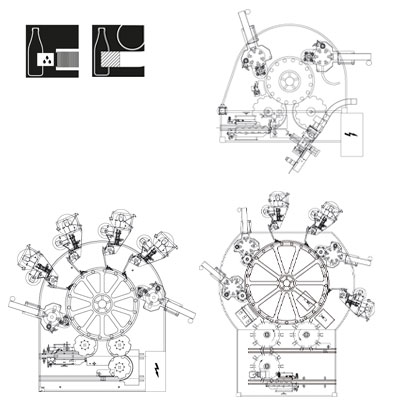

Oil lubricated gears provide a long life service

Hermetically condensate protected

Exchangeable and asjustable wear resistant glue pallets

Adjustable glue pallets for optimum glue pattern

Automatic ” no bottle – no label – no glue“ is standard on the machine

Label setting unit adjustment through implemented overlay gear, even while machine is running

Maintenance free, heated glue pump is standard

The job of a cold glue labeling machine is to apply pre-cut labels to many types of containers. Cold glue is perfectly suitable for several label applications, and an ideal application method for heat-sensitive materials while also reducing the risk of burns for laborers. It is suitable for applying front, shoulder, and neck ring labels as well as tamper-evident seals in humid environments and on wet surfaces. It is also common to couple cold glue with hot glue or pressure-sensitive labeling aggregates on one rotary cut & stack cold glue labeler to achieve highly personalized labeling.

When you think about labeling and its impact on a brand’s overall impact on consumers, it is important to get every step right. Label types are naturally tied to the type of adhesive employed. Cold-Glue Labels are known as cut-and-stack labels; they are almost exclusively made of individually cut paper arranged into 1,000 count stacks and are generally inexpensive. These types of labels come uncoated and require that the labeler apply the cold glue via pallets and rollers at the time of application. Labels can alternatively be produced on other substrates such as metalized paper and some transparent polymers. Cold-Glue Labels can also be laminated, foil-stamped, or die-cut to nearly any shape for added pizzazz.

Newly constructed drive

Label lengths up to 180 mm and 250 mm

Solid four-legged container mound with quick fasteners

Adjustable dipping depth of pallets offers higher reproducibility

Reliable drip protection due to the integral glue tray design

Corrosion protection and innovative aggregate sealing

Improved maintenance and cleaning capability

Patented overlay gearbox for optimum label positioning adjustment while machine is running

Oil-bath-lubricated wet glue aggregate for maximum labeling accuracy and a long service life

Clip-lock orientation (optional)

Aggregates with height adjusting facility (optional)

3-dimensionally adjustable glue segments for homogeneous glue pattern

Divided and precisely adjustable glue knife with over-gluing function

CIP cleaning for gripper finger for perfect label transfer

Blowing long labels onto the gripper cylinder sponge prevents spiral offset

Setting to different container diameters by swivelling the aggregate

Aggregates that can be mechanically or electro-pneumatically uncoupled

Heated glue pump for optimum glue temperature

No bottle – no label – no glue – automatic

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary LabelersSpoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

28 February, 2022 Rotary Labelers Trouble Shooting