5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary Labelers

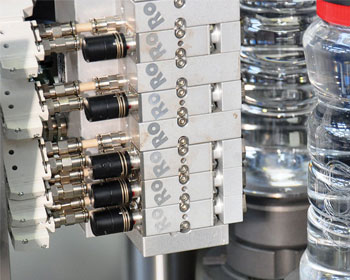

Autonomous dispensing unit with quiet running servo motors

Optional modular dispensing unit combinations

Easy positioning of the labels by 4/5-way setting

Manage multiple labeling positions

Intelligent label management and clamping system for label transfers

Non-stop labeling due to double roll alignment

User-Friendly

Low Labeling Costs

Dry, damp, and wet bottle dispensing

Economical continuous operations

Continual production with simple label addition during operations

Hot Melt is a polymer-based adhesive that is an excellent alternative to waterbased-glue because it is fast-acting and withstands humidity. This labeling technology has been the preferred method employed in bulk production that requires high output demands with a fast set speed and the ability to meet and maintain a high level of hygiene.

Holt Melt Labeling is especially appreciated in the cold food industries that need product packaging labels that adhere quickly and easily, conform to various types of packaging, and stay in place for the product’s life cycle. One of the greatest benefits of hot melt adhesives is that they deliver unmatched versatility for any temperature application – warm or cold.

Our specially designed automatic rotary labeler performs economical wrap-around labeling of glass, plastic, and metal containers.

Hot melt can be employed with different label sources, either roll stock (from a roll) or cut & stack (from a magazine). Cut & stack labels are printed on large sheets in bulk and then cut to the desired format and stacked. They are ideal for labeling large volumes and are available on various materials. They are easy to load into the labeling machine’s magazine, and labels can be restocked continuously – without ever stopping the machine!

Cut & Stack labels offer flexibility and are cost-effective for large and mid-sized companies. They are used in a variety of industries and are typically applied by overlapping the label and gluing it to itself (wrap-around). However, they are sometimes glued directly to a bottle, like in the case of glass beer bottles. This type of labeling is frequently employed to label beers, beverages, food items, and household goods.

GERNEP-HotSpot nozzle system offers low glue consumption application to bottles or containers

Optimized brushing minimizes spiral offset commun with more extended labels

End gluing ledge for perfect pasting of the label overlap

Robust, torsion-resistant tripod and adjusting scales for precise & repeatable glue application from the nozzle system

Possibility of spiral or spot application for the start gluing, depending on bottle shape & labeling material

Our hot melt system prevents penetration of condensation and avoids the continuous cooling and reheating typical of other roller gluing systems

No bottle – no label – no glue – automatic

Our explicitly designed fully automatic labeler enables the economical wrap-around labeling of glass, plastic, and metal containers.

Due to its modern and operator-friendly circular design, the ROLLINA can operate hot melt labeling from the magazine. The Rollina-R is a combined thechnology labeling system and comes equipped with other aggregates for pressure-sensitive and/or cold glue labeling.

Autonomous dispensing unit with quiet running servo motors

Optional modular dispensing unit combinations

Easy positioning of the labels by 4/5-way setting

Manage multiple labeling positions

The performance and configuration of our labeling machines are customizable and adjustable to conform to the individual requirements of specific industries and applications.

Optionally, this labeling system allows combinations with one or multiple wet glue labeling and/or pressure-sensitive labeling units.

All Gernep machinery provides the flexibility to add container orientation systems and supplemental labeling. Labeling control can be set at the planning stage or retrofitted.

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary LabelersSpoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

28 February, 2022 Rotary Labelers Trouble Shooting