5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

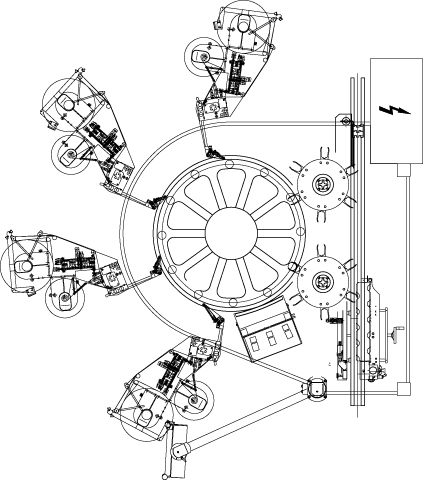

Bottle Labeling Design Rotary Labelers

Currently one of the most used applications for labeling worldwide, Pressure Sensitive Labeling Systems offer a perfect balance between cost and ease of application which is why they are used across nearly all consumer goods industries today.

PS Labeling offers a clear advantage over other labeling technology mainly due to its easy integration with existing lines. It also provides a great variety of substrates and adhesives that lend themselves to an eco-friendlier manufacturing approach.

Our Soluta Rotary Labeler offers the flexibility required for today’s fast-paced packaging industry, labeling on nearly any surface, shape, and size of container or bottle. While you may raise a brow at the slightly higher initial cost of such machinery, crunching numbers will validate the savings made over time when you consider the substantially lower changeover, cleaning & down-times, and the lower price of label size parts. It is also worth noting that a whole world of options opens up to you in terms of size, shape, materials (which range anywhere from paper to clear plastics and foils), and finishes. That’s a sure way to make sure you can stand out from the crowd and adapt to changes in your niche quickly and efficiently.

Equipped with PLC and perfectly synched servo-driven applicators enhance functionality! Multiple labeling parameters can be easily stored and retrieved. Intelligent label management makes A multiple label application is a snap. With up to 8 label applicators mounted to one frame – each applying to a specific position and angle by 4/5-way setting, it couldn’t get much easier!

Pressure Sensitive labelers can be tailor-made to house up to 8 label applicators to achieve a variety of label placements nearly anywhere and in any configuration (neck, body, top, tamper-evident, etc.) particular to your brand. With multiple aggregates the rotary labeler can tackle any challenge head-on!

Let it also be said that the label applicators may be a multiple of one same aggregate or a combination of aggregates. For example, the beer, and wine & spirits industry often mix the efficiency of Pressure Sensitive Labeling with cut & stack cold glue labeling. Of course, hybrid systems have advantages and disadvantages, so be sure to reach out to us for more details!

Extended booklet content labels or multi-panel labels often required in various consumer goods industries like pharmaceuticals, nutraceuticals and foods require more text than traditional flat labels can provide. Booklet Labels offer a convenient space-saving way to incorporate multiple languages, instructions, application processes and warnings while maintaining brand integrity.

Pressure Sensitive Labeling is also taking the world of craft brewing by storm as a refreshing alternative from traditional plastic shrink sleeves and more costly inkjet printing techniques. It offers a great alternative for any ecologically inclined company as it is possible to order lwash-off adhesives that offer remarkable adherence while simultaneously leaving the can’s surface residue-free after removal.

As you might expect not all labels will withstand the conditions that beer cans are exposed to. Thankfully materials and inks that are resistant to water, humidity, cold and ice are widely available today. Pressure-Sensitive labeling aggregates handle a large variety of label materials that will look and feel great even when exposed to the harshest conditions.

Applying tamper-evident labels (L-Shape application, or a U-Shape) for food and beverage, chemical products like cleaning and laundry detergents, cosmetics, and over-the-counter drugs is complex yet delicate task that requires design expertise and precision. GERNEP Pressure-Sensitive Labeling machinery includes an HMI for easy setups and adjustments, a PLC for precise servo-driven label application as well as sled-mounted label applicators to enhance efficiency and reduce down-times.

Need advice on planning tamper-evident or excise tax labeling operations? We would be delighted to assist you. Contact us directly or drop us a line!

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

Bottle Labeling Design Rotary LabelersSpoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

Rotary Labelers Trouble Shooting