- All

- Cold glue labeling

- Pressure Sensitive Labeling

- Hot Melt Glue Labeling

- Combined Labeling

AUTOMATIC LABELING MACHINES

What is an automatic Labeling Machine?

Automated labeling machines are engineered to apply labels to various products effortlessly. Semi-automatic & fully automatic labelers are the step up from manual labeling operations for manufacturers who need to meet growing customer demands and efficiency handling increased production volumes.

From food and beverage packaging to cosmetics, personal care, chemicals, pharmaceuticals and more, an automatic labeling machine is invaluable to the manufacturing and packaging sectors. With cutting-edge technology and swift mechanisms to streamline the labeling process, manufacturers can ensure efficiency, precision, and convenience. Ultimately, investing in an automatic labeling machine translates to investing in prosperity and advancement.

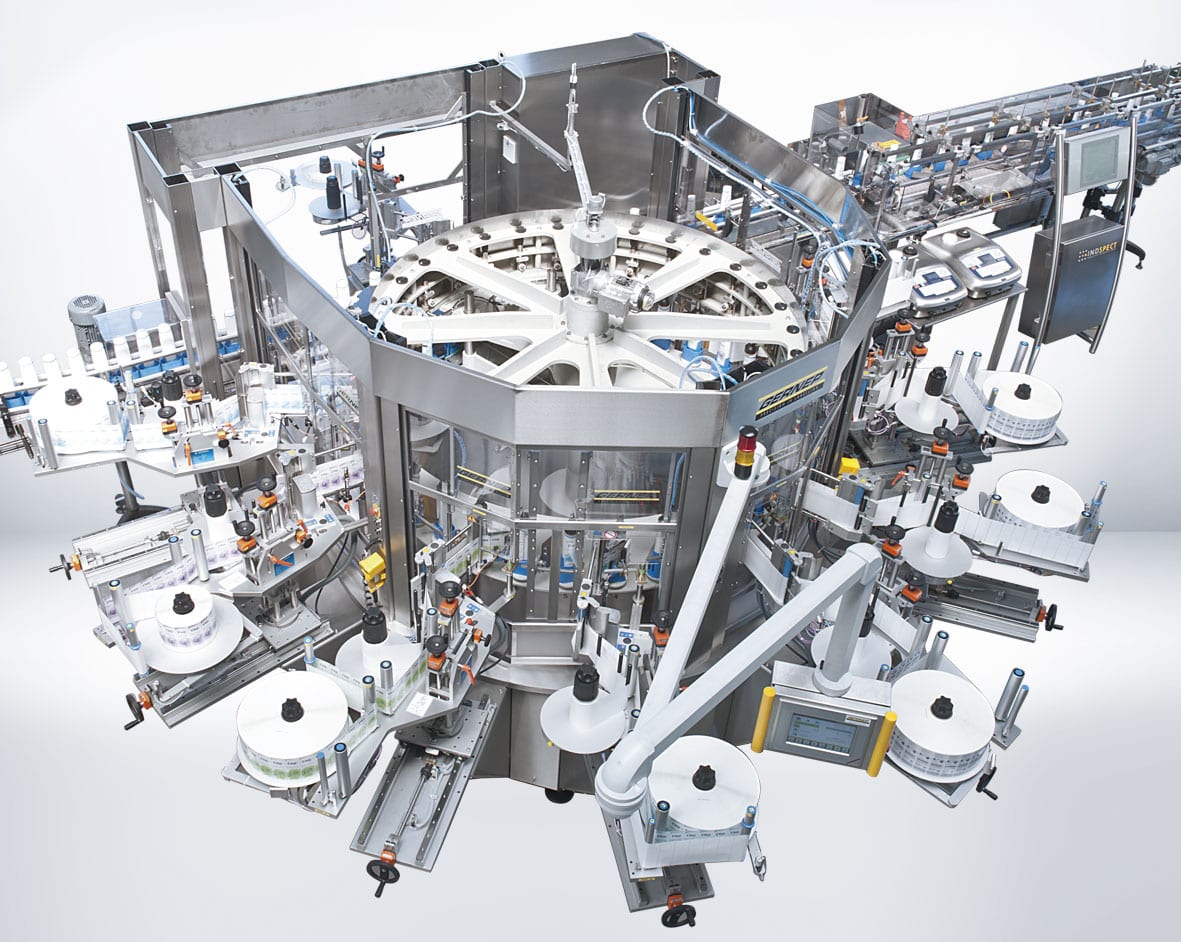

What is an Automatic Rotary Labeling Machine?

Rotary labeling systems employ a rotating mechanism to apply labels onto products. Rotary labelers offer flexibility in label placement and orientation, accommodate various product shapes and sizes, and have several advantages over a linear system. They enable higher speeds and deliver continuous label application, eliminating unnecessary pauses and reducing downtimes – ideal for large-scale manufacturing. In contrast, a linear system is standard for smaller production lines.

What Are the Different Types of Labeling Machines?

Many types of labeling equipment are available to automate label application – the trick is to understand what each offers and if they are well suited to your current and future application requirements.

Semi-Automatic Labeling Machines:

Tabletop Labeling Machines: These machines are compact and designed to be placed on a tabletop or workbench. They typically have a semi-automatic labeling process, with manual product placement and automatic label application. These come in various application configurations like tamp, blow, wipe, and wrap.

Hand-Fed Labeling Machines: These linear machines can be used as stand-alone solutions or integrated into a production line. They require an operator to manually feed and/or remove products onto the conveyor line leading in or out of the application. They are helpful for labeling small batches & lower-speed productions or when mobility is required.

Automatic Labeling Machines:

Linear Labeling Machines: These machines house a magazine to feed or integrate with a conveyor system, automatically feeding products to the labeling station. They offer mid-speed labeling and are suitable for small to intermediate-production rates.

Rotary Labeling Machines: Rotary labeling machines use a rotating mechanism to apply labels to products. They can handle a wide range of product shapes and sizes and are ideal for high-speed labeling.

Front and Back Labeling Machines: These automatic machines can simultaneously apply labels to both the front and back of products, enhancing efficiency for containers or packages requiring labeling on both sides.

Print and Apply Labeling Machines: These machines combine printing capabilities with label application. They can print variable information and automatically apply the labels to products, often used for high-volume packaging lines.

Ask us to select an approprite model for your application

This is not an exhaustive list but merely a few examples of the semi-automatic and automatic labeling machines available to manufacturers. The choice depends mainly on production volumes, labeling speeds, label placement requirements, and product characteristics.