5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary Labelers

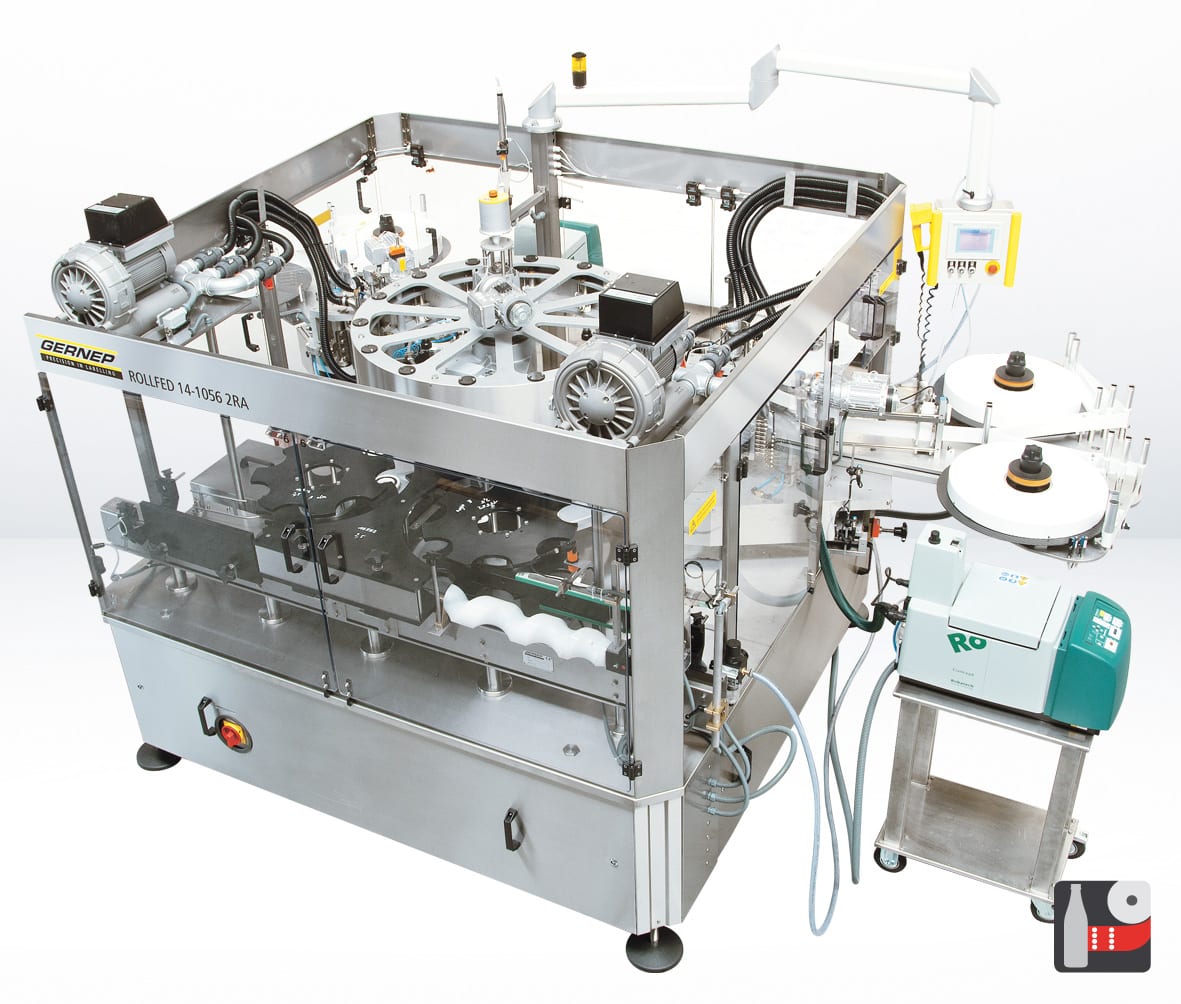

Over the past 20 years, the PS labels have become very popular across many categories. Versatility, no machine cleaning, easy adjustment and low cost of change parts are some of the reason why the pressure-sensitive labels are widely adopted. Offered in different material like paper or clear plastic, they let the consumers see your products and offers unlimited graphical possibilities. Pressure-sensitive labels are supplied in rolls and Gernep can install up to 8 pressure-sensitive label applicators on the same rotary labeler.

Most round plastic bottles of spring water and soft drink are decorated with paper or film labels applied to the bottles with hot melt. It is easy to recognize hot melt applied labels, when you peel-off the label at the seam, the leading and trailing edge of the label will have glue on it, but not on the rest of the label. The labels applied with hot melt can be supplied on rolls (hot melt rollfed labeler) or in stacks (hot melt cut & stack labeler). The main advantage of this labeling technology is the low cost of labels.

Cold glue (wet glue) labelers have been around for many years and they still have their place today in many industries such as beer, wine and mineral water in glass bottles. The cold glue applied labels are supplied in stacks (cold glue cut & stack labelers) and are very economical and allow non-stop, high speed production. Because of the way the glue is applied to the labels, the length is limited and those labels typically cover only a portion of the radius of round bottles. You will notice that most beer bottles decorated with cold glue labels have a front and a back label to provide more space to give information to consumers.

BOTTLES SHAPE, SIZE AND MATERIAL

When it comes to wrap around labeling, it’s important to clearly identify the range of products you want to run on the labeler. For example, do you need a wrap around labeler that can handle tall skinny bottles and large diameter jars? Oversized bottles, tapered shape and recessed areas might also require specific equipment. Fortunately, some wrap around labeling systems are flexible enough to handle a wide variety of round containers, provided the manufacturer knows before designing the machine. For example, it is possible to apply very long labels (like 20’’ long), but it will require a specific attachment.

FULL WRAP AROUND LABELING OR PARTIAL WRAP AROUND LABELING?

Full wrap labeling means the leading and trailing edges of the label will meet on the bottle, either overlapping or with a small gap. Depending on the quality of the bottles, the labels may not be straight, and this will result in labels applied in spiral (or skew) where the leading and trailing edges will not be aligned. The end-result is a bad looking product on the shelves, which may affect the perceived quality of your products. Some attachments are available to avoid skew labels by straightening the bottles prior application.

Partial wrap labeling is simple to perform with pressure-sensitive labels, but it may prove a little more challenging with cut & stack labels. Cut & stack labels (also known as pre-cut labels) are literally stacks of paper or film without adhesive backing, which means the labeler must apply glue to the label or container for the labels to stick. Generally, a cold glue labeler will be better suited for partial wrap labeling than a hot melt labeler. The main reason being the complete backing of the labels is covered with adhesive with cold glue technology, but only the leading and trailing edges with hot melt adhesive. As you can imagine, there is also glue saving factor to take into consideration when investing in a wrap around labeling machine. Each project must be properly evaluated to determine the best option.

FRONT AND BACK LABELING WITH A WRAP LABELER

While it may not be the first thing that comes to mind for a wrap-around labeler, it is possible to apply front and back labels with a wrap labeler. The most common applications are in the wine industry, you can either apply front and back labels from the same web/roll, or from two separate rolls.

Front and back labels are often used on large round bottles and beer bottles to create a distinguishable space where you can see the product through the packaging. However, this requires “easy-to-adjust” wrap around label applicators to make sure the front and back labels are well-aligned with an equal space between each other. Ideally, the fine tuning of both label placement can be adjusted on the fly during production. Thanks to Gernep’s patented overlay gearbox, this is possible by simply turning a handle during production, even at full production speed.

Coming back to the first paragraph, we can add that it is possible to apply front and back labels on cylindrical bottles with an entry-level inline labeler. In order to do this, the wrap labeler will require to either have a vacuum wrap belt or a 3-point aligner. Both option can give great results for a reasonable investment, however for higher speed or application requiring orientation, neck label, tax label or vision inspection, a rotary wrap around labeler will offer enhanced possibilities. Again, it is all a question of properly identifying your needs ahead of time.

.

WRAP AROUND LABELER PERFORMANCE

There are many styles and sizes of wrap around labeling, directly affecting the speed of the production line. Do you need to label 50 or 500 bottles per minute? For example, a craft brewery can create a small batch seasonal beer and appreciate using a basic inline wrap labeler. However, for larger scale production, a fully automatic rotary wrap around label applicator is a must.

.

HOW MUCH FLOOR SPACE DO YOU HAVE FOR YOUR WRAP AROUND LABEL APPLICATOR?

After having determined the container specifics, the required performance level and the type of labels to use, you need to consider the available space on your production line. This might not be a problem if you have a lot of space available or if you are designing a brand-new line, but if you are replacing underperforming equipment or have limited space, the overall footprint is definitely something to take into account at the early stage.

Besides floor space, make sure that the selected wrap around label applicator is integrated properly in your bottling line. Obvious factors to consider are the overall labeler length, the working height of the conveyor and upstream and downstream machine communications. Less obvious, but equally important for OEE (Overall Equipment Effectiveness) is the space for bottle accumulation before and after the labeler. Too little accumulation will frequently stop and start the labeler, which can potentially create problems.

CHOOSING THE RIGHT LABELS

Depending on the characteristics of your products and your work environment, the choice of the label material and adhesive is critical. For example, it is very different to apply a label to a wet bottle in a cold environment compared to applying a label to a hot-filled jar at 85⁰ Fahrenheit. It is always a good idea to bring together the label supplier and the machine builder to make sure they agree on the best label/machine combination for your products.

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary LabelersSpoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

28 February, 2022 Rotary Labelers Trouble Shooting