24 Sep High-Accuracy Labeling Solutions for Complex Containers

The Rotary Labeling Advantage

Labeling non-standard or complex structures like conical, ovaloid, multifaceted or multi-curve bottles, jars or containers can be tricky. Industries like pharmaceuticals, cosmetics, food, and beverages are turning to high-speed rotary labeling machines that are better equipped to handle this type of packaging. Rotary labelers achieve precision at scale – they’re the go-to choice for high-volume, complex container labeling.

The Challenge: Labeling Complex Containers

Traditional linear labeling solutions struggle with complex shapes, and with good reason. Linear labelers are designed have products travel along a linear axis, it can’t adjust the position of the container or apply wipe down on all surfaces.

For complex containers, the lack of rotation on linear solutions makes it difficult to position the label on the correct part of the container’s surface. Thanks to the cams, container orientation and puck handling systems available on rotary labelers, it is possible to manipulate curved, multipaceted and unstable containers in such a way that the label can perfectly conform to their shape.

All labeling machines require wipe-down accessories like rollers or brushes to smooth the label once it is applied to the container surface. The limited axis of linear labeling solutions works well on flat surfaces or cyclindrical containers however, for irregular containers it is impossible to apply even pressure across the whole season. This mosly leads to adherence issues, like skewed labels, bubbling, wrinkling and a whole host of frustrating issues.

By addressing these limitations in container orientation, manipulation, and the wipe-down process, rotary labeling machines provide far better results for complex containers than linear systems.

Advanced Features for High-Accuracy Labeling Solutions

Rotary Labeling machines come equipped with cutting-edge features that ensure consistent, high accuracy labeling across various container types. These machines are capable of applying multiple labels – such as front, back, and neck labels-simultaneously, which is particularly interesting for complex containers that have original branding. Precision is achieved by using high-precision servo-motors which control the exact positioning and minimal variability even at speeds reaching 50 000 bph. Aditionally, non-stop labeling solutions allow continuous labeling without downtime, significantly boosting production time.

Bottle Plate

Control System

Container Orientation

Mechanical or Servo Systems

Non-Stop

Continuous Labeling

Complex Containers Across Various Industries

Rotary labelers excel in handling complex container shapes commonly found in the following industries:

- Cosmetics & Personal Care

- Berverage Industry

- Pharmaceuticals and Healthcare

- Household and Cleaning Products

- Luxury goods and Speciality Foods

They benefit significantly from rotary labelers due to their ability to handle complex shapes with precision. Rotary labelers’ rotating platforms ensure accurate label placement on curved and non-standard surfaces, while their non-stop operation and camera-based orientation systems maintain high speeds without sacrificing quality. These features allow for simultaneous application of multiple labels, enhancing efficiency and maintaining brand integrity across diverse packaging types, which is especially crucial in markets where presentation is key!

Most Common Issues – Labeling Irregularly Shaped Containers

Labeling irregularly shaped containers presents several challenges due to their non-uniform surfaces and unique designs. Some of the most common problems include:

- Label Misalignment: Irregular shapes like ovals or cones can lead to misalignment, where the label doesn’t sit properly on the container. This occurs because the label applicator struggles to adapt to the uneven surface, causing the label to skew or wrinkle.

- Poor Adhesion: Containers with curves or textures often cause the label to peel or lift off after application. This happens when there is insufficient surface contact between the label and the container, especially on containers with sharp curves or angled surfaces

- Air Bubbles and Wrinkles: When labeling curved or contoured surfaces, air bubbles or wrinkles can form under the label. These imperfections can reduce the aesthetic quality of the product and cause the label to wear off more easily

- Inconsistent Label Placement: On irregular containers, ensuring consistent label placement is difficult. Linear labelers, in particular, may struggle with orientation, leading to labels being applied at different angles on each container

- Complex Wipe-Down Process: After the label is applied, many machines use brushes or rollers to ensure the label adheres smoothly. However, on irregularly shaped

containers, these wipe-down processes often fail to apply even pressure, leading to incomplete adhesion and aesthetic issues

Mitigate these challenges with rotary labelers, which allow for greater flexibility in handling non-standard container shapes.

Key Considerations to Choose a Labeler for Your Irregular Containers

When selecting a labeler to best adress your labeling needs, you have much to gain from understanding the long-term benefits. Rotary labelers offer an attractive return on investment (ROI) because it reduces downtime and minimizes errors which lead to label waste – both of these considerations positively affects overal production efficiency!

Rotary labelers are also customizable, with the ability to incorporate on or multiple like Hot Melt, Cold Glue and Pressure Sensitive label applicators, providing extreme flexibility to manufacturers everywhere. This provides the ability to adress variances in labeling for different product lines and different shapes – not to mention the non-stop operation which means fewer interruptions and less maintenance- making them a durable and reliable solution for high-volume production environments.

Other nice-to-haves are the ability to integrate seamlessly with pre-existing machinery and equipment further enhances production flow, while modern sustainability features—like supporting eco-friendly label materials—align with growing demands for greener operations. For manufacturers focused on optimizing both performance and sustainability, rotary labelers present a compelling choice.

An Unmatched Labeling Solution for Irregular Containers

Rotary labelers are an unmatched solution for industries dealing with irregularly shaped containers. Combining high precision, flexibility, and speed, they are invaluable for businesses looking to optimize their production lines while ensuring consistency and accuracy. Their advanced features, such as non-stop operation, multiple labeling capabilities, and seamless integration with existing systems, help increase throughput while reducing maintenance-related downtime.

Furthermore, rotary labelers meet stringent industry regulations, making them ideal for sectors like pharmaceuticals, cosmetics, and food and beverages. As sustainability becomes increasingly important, the ability to use eco-friendly materials further enhances their appeal. For businesses seeking a reliable, versatile, and future-proof labeling solutions, rotary labelers are a compelling choice that can enhance both operational efficiency and product presentation.

Wrap Around Labeling Machines in North America: Why Choose Gernep

Gernep wrap around labeling machines, powered by Krones technology, deliver precision, speed, and sustainability for North American manufacturers. From food and beverages to cosmetics and pharmaceuticals, our solutions transform bottles, jars, and cans into 360° marketing tools - boost efficiency, ensure compliance, and stand out on the shelf.

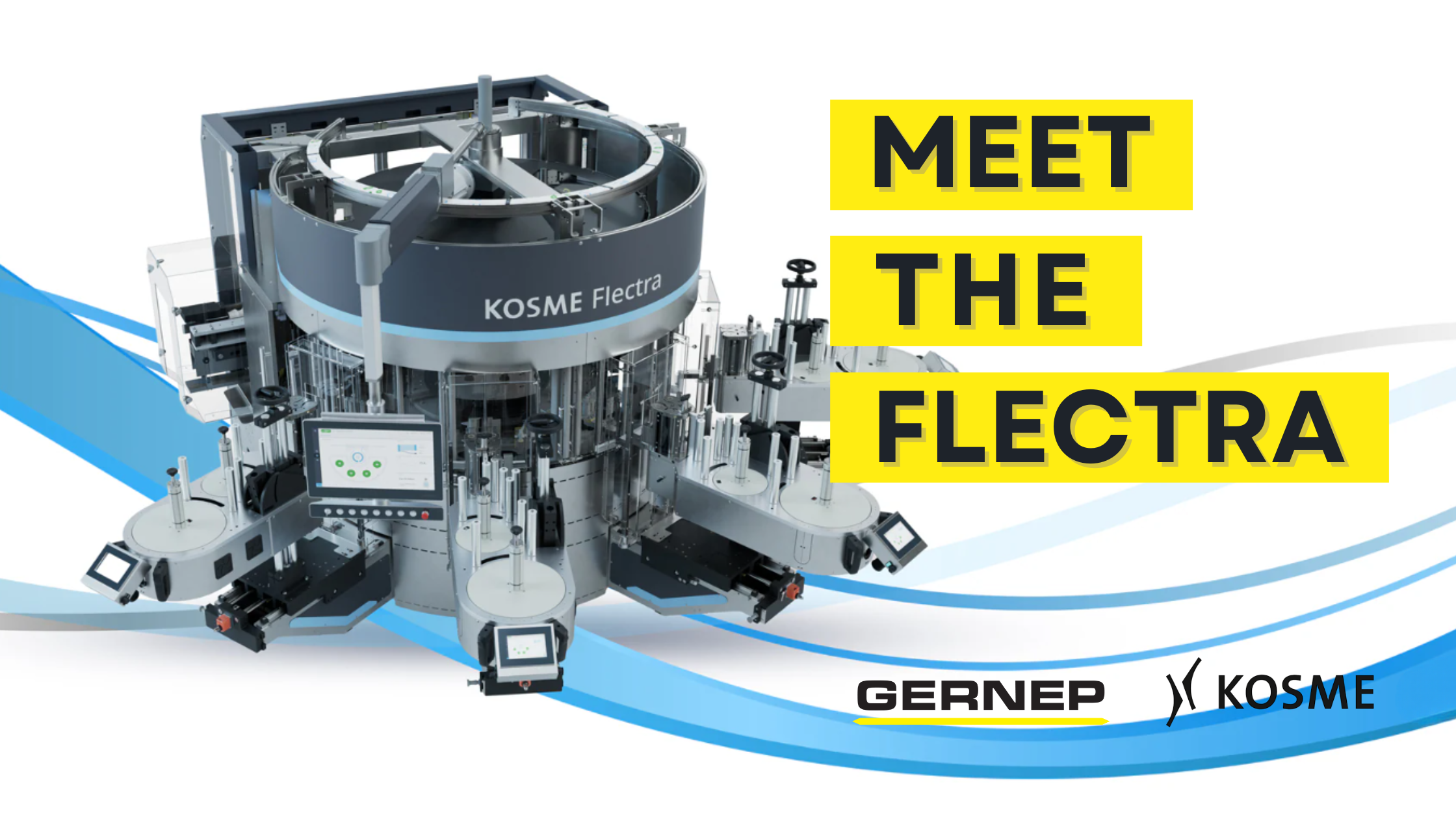

FLECTRA: A New Flexible Labeling Machine for Diverse Industries

Discover how Krones’ new Flectra labeling machine brings unmatched flexibility, precision, and hygiene to manufacturers. Designed for brands with diverse SKUs, strict compliance needs, or frequent changeovers, Flectra helps reduce waste, cut downtime, and streamline production.

Is Your Pharma Labeling Keeping Up?

North American pharmaceutical production is under pressure to move faster and comply with tighter traceability mandates. In this article, we unpack why automatic rotary labelers are essential for GMP-compliant, high-speed lines that integrate serialization and inspection.

Why Labeling is More Than Just a Sticker

Labeling is no longer just a finishing step — it’s a strategic driver of speed, compliance, and product appeal. As mid-to-large manufacturers across North America face rising demand, evolving regulations, and SKU complexity, rotary labeling machines are proving to be the high-speed, high-precision solution built for scale.

Reducing Downtime in High-Speed Labeling: Best Practices

Maximize uptime in high-speed labeling with preventive maintenance, error-proofing, and automation. Learn how to keep your rotary labeling machines running smoothly for maximum efficiency and productivity.

High-Accuracy Labeling Solutions for Complex Containers

Precision is key when labeling irregularly shaped containers. Our pre-modular labeling solutions ensure the highest label application accuracy, even on the most complex containers. Our machines adapt to a wide range of shapes. providing flexibility without compromising on quality!

Celebrating A Prosperous Partnership

Explore the story of how Gernep and Robatech have been glued to success, providing cutting-edge hot melt labeling solutions that help manufacturers across various industries stay ahead of the curve...

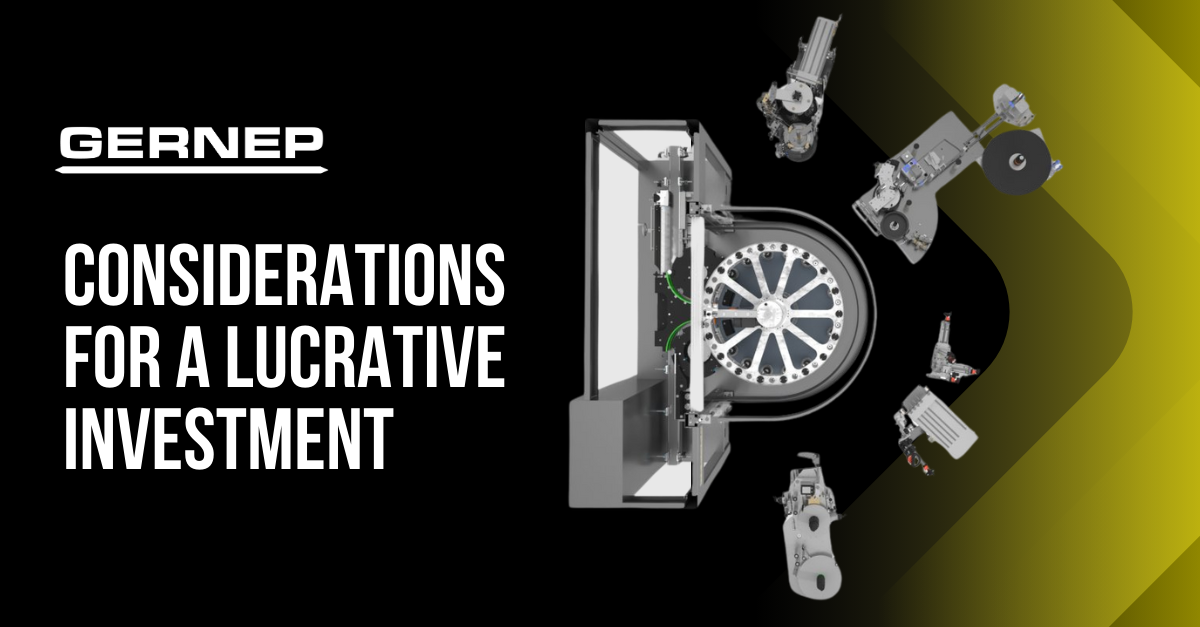

Investing In a Rotary Industrial Labeling Machine

Investing in a new rotary labeling machine can significantly enhance your production efficiency and product quality. In our latest blog post, we discuss essential considerations such as the total cost of ownership, spare parts availability, seamless integration with...

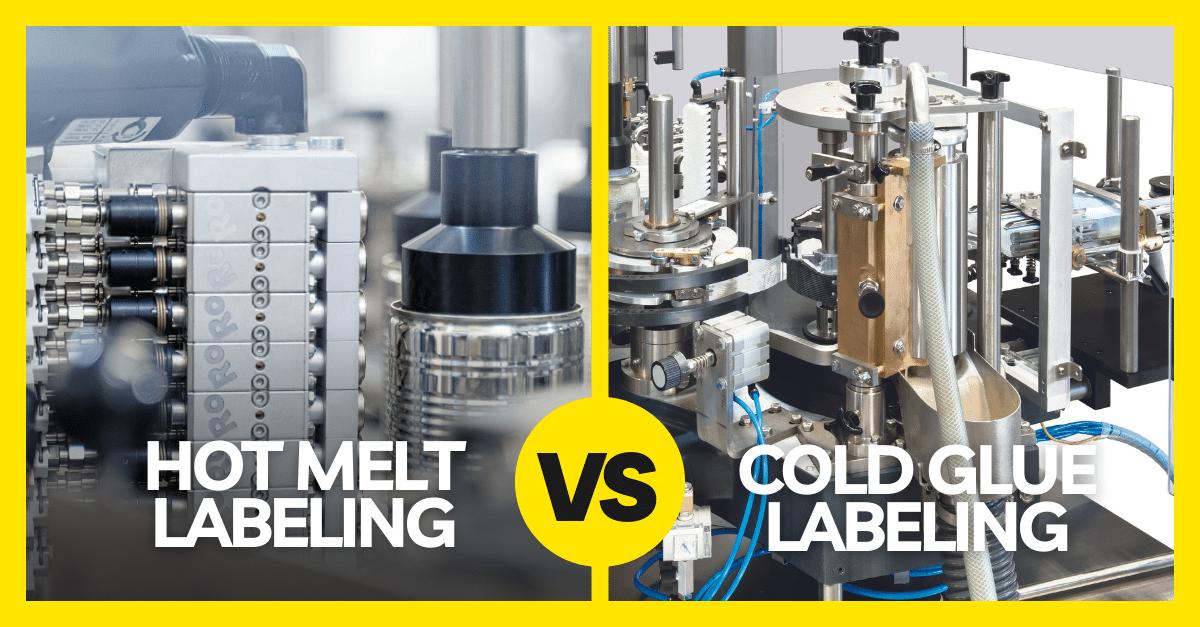

Hot Glue vs Cold Glue Labeling: Expert Comparison for Rotary Labeling Machines

In this comprehensive blog post, we compare hot melt and cold glue labeling technologies for rotary labelers, exploring their unique benefits and applications. Learn about key differences to consider which...

Crafting Elegance with Transparent Film Labels

With Gernep's Soluta, Runamok mastered the sophisticated "No-Label Look" that sets them apart from the competition. By partnering with Gernep, they've overcome technical challenges, ensuring each bottle is a testament to their dedication to excellence.

The Evolution of the North American Beverage Industry

Adapt swiftly to North America's dynamic beverage industry with customizable labeling machines. Embrace market changes through enhanced flexibility, sustainability, and efficiency and stay ahead thanks to systems designed to ensure your operations are future-proofed...

Rotary Labeling Technology Demystified

The right labeling technology can make a significant difference in your production line. In this blog we offer a comparison of the different labeling technologies available, so that you are selecting the right machine to get your job done as efficiently and cost-efficiently as possible.

Rotary vs Linear Labeling Machines: A detailed Comparative Analysis

Explore the essential differences between rotary and linear labeling machines in our comprehensive analysis. This detailed guide covers speed, efficiency, versatility, and cost, helping you choose the right labeling solution for your business needs.

A Deep Dive into Rotary Labeling Machines for CPG Industries

Where innovation and efficiency are paramount, a transformative solution is making its mark on CPG industries - rotary labeling machines. Join us on a journey of discovery as we unravel the unparalleled efficiency, accuracy, and versatility that these machines bring to the table.

Cutting-Edge Labelers Take the Spotlight at Pack Expo Las Vegas 2023

Discover the Future of Packaging with Gernep at Pack Expo Las Vegas 2023! Prepare to embark on a journey that will redefine your perception of packaging.

Tips for Buying Used Labeling Machine

Buying used labeling equipment can be a cost-effective solution that allows you to acquire high-quality machinery while saving money. However, it's essential to navigate the process wisely to ensure a successful purchase. Here are some valuable tips to consider when...

Maximizing the Labeling Efficiency of Unstable Containers with Puck Conveyors

Gernep Puck Conveyor Systems are specifically designed to maximize labeling efficiency for even the most unstable containers. Face the challenge head-on with Gernep and streamline your labeling process.

New Generation Labelers: SlimDesign featuring SecrureLift

Over 40 years of experience go in to every new SlimDesign machine built. The new generation of Gernep machines are more versatile and compact that ever. With the new SecureLift security guards we also make good use of vertical space to provide a better access...

On a Roll Thanks to a New Labeling Machine

Dimachem has been providing chemical solutions for various applications since 1972. A recent expansion led to the acquisition of a rotary hot melt labeling machine to complete a packaging line dedicated to producing a new line of disinfectants.

No-Label Look

The no-label look has been a favorite among many manufacturers for a few years now. It is a cost effective solutions and provides a sophisticated way to differentiate yourself in way that consumers appreciate.

Join us at Pack Expo 2022

The biggest packaging show is just around the corner! Drop by Pack Expo Chicago 2022 south hall - booth 4064 to meet with the Gernep team!

Bartling Trusts Gernep for Modernizing

Bartling GmbH specialised in the production of plastic cup packaging for the food industry has partnered with Gernep to modernize its outdated labeling machinery and enhance its container labeling portfolio.

7 Tips for Chemical Labels

Abiding by all consumer chemicals labeling regulations can be tricky business, so we've rounded up useful links that will help get you up to speed!

5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product.

5 Temperature-Related Labeling Issues

Spoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues.

Butcombe Brewery Trust Gernep Machinery

Well known Uk Craft Brewer, Butcombe Brewery singles-out Gernep's Soluta, efficient pressure-sensitive machinery for it's home and co-packaging operations.

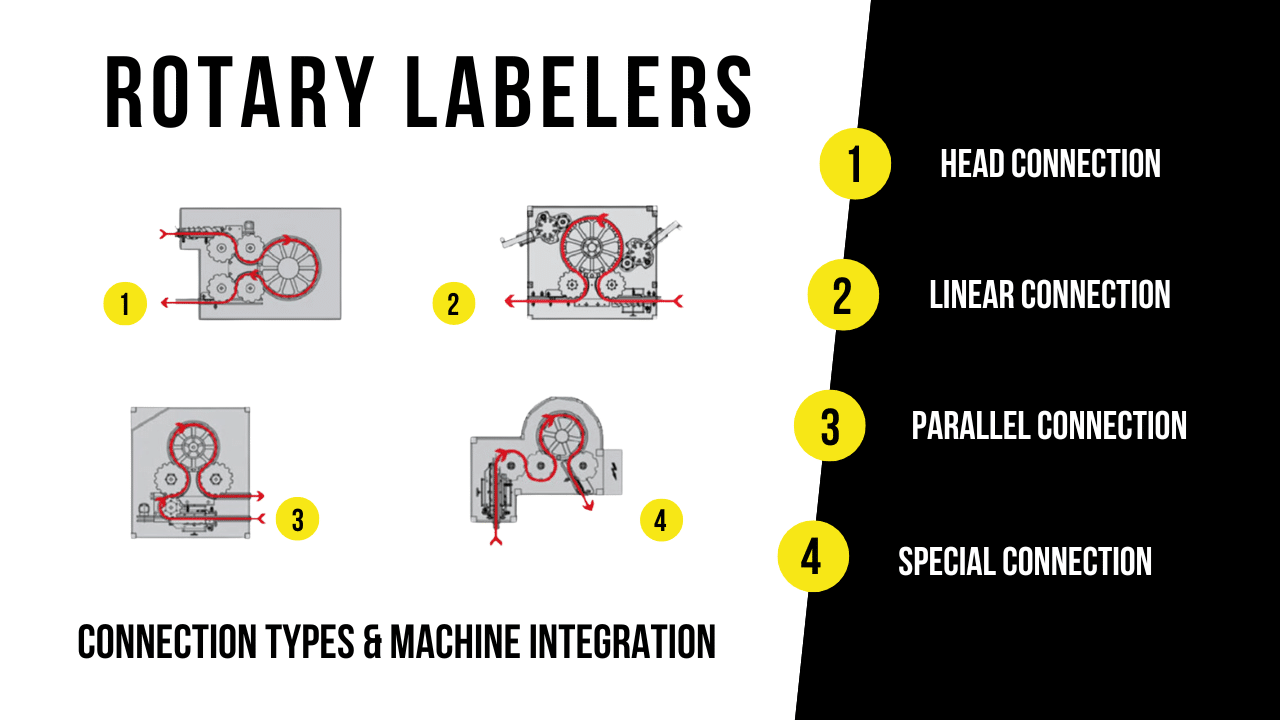

Rotary Labelers: Connection Types & Machine Integration Rotary Labeling Machines

Planning to retrofit or add new machinery is always a challenge but also a fantastic opportunity to optimize your plant's floorspace

Hot melt pressure sensitive adhesive vs hot melt liquid glue

Hot melt pressure sensitive adhesive vs Hot melt liquid glue - making the proper choice in labeling technologies will affect accuracy, cost and maintenance.

Replacing the Shrink Sleeve

Effective September 1, 2021, the province of Québec’s Recyc-Quebec banned the use of shrink sleeves. The switch to pressure-sensitive labeling will have an immediate impact improving the sustainability of beverage packaging and th “Closed Loop” recycling process.

Pressure Sensitive Labeling: Benefits, Applications, and Best Practices

Pressure Sensitive Labeling appeal is growing as they adapt to shifting market trends as well as offering the perfect balance between cost, brand appeal and efficiency.

Pioneer of Ecological Cleaners Trusts Gernep Labeling Machines

Sonett was a trailblazer for ecological cleaners and detergents in Europe who have trusted Gernep's “Made in Germany” quality machinery, labeling solutions, and solving unexpected discrepancies among others.

Labeling Glass Jars and Containers

Labeling molded glass is a touchy operation and depends on a few factors that need careful consideration. This rotary labeler hit the mark when it came to effective tamper evident labeling applications

Selecting the right beer labeling equipment for your needs

Efficient labeling equipment will dramatically increase productivity and pay for itself quickly by immediately increasing production.

Cannabis Industry Trends of 2021

Cannabis companies and their ancillary partners face a unique set of packaging challenges and constraints, one of which is the exact positioning during the application of excise stamps on their packaged product. Handling small sizes and exact positioning at high speed is where we come in.

Listing of refurbished labelers – March 2020

Consult the following to learn more about our refurbished machines currently in inventory.

Soluta Rotary Labeler for the Wine and Spirits Industry

Running multiple botte shapes is common among wineries and distilleries and a labeling machine that achieves fast changeovers and a configuration providing zero downtime could be your greatest ally.

Why most craft brewers are choosing rotary labelers for beer bottles

Despite many craft brewers investing into canning lines, learn how our efficient, rotrary labelers enhance glass bottle presentation, improves label placement, and gives your beer brand a standout shelf presence.

5 things to know about labelers

Buying a new labeling machine can be a big investment depending of your production requirement. We hope to be able to demystify the different types of labeling systems and help you make a sound decision.